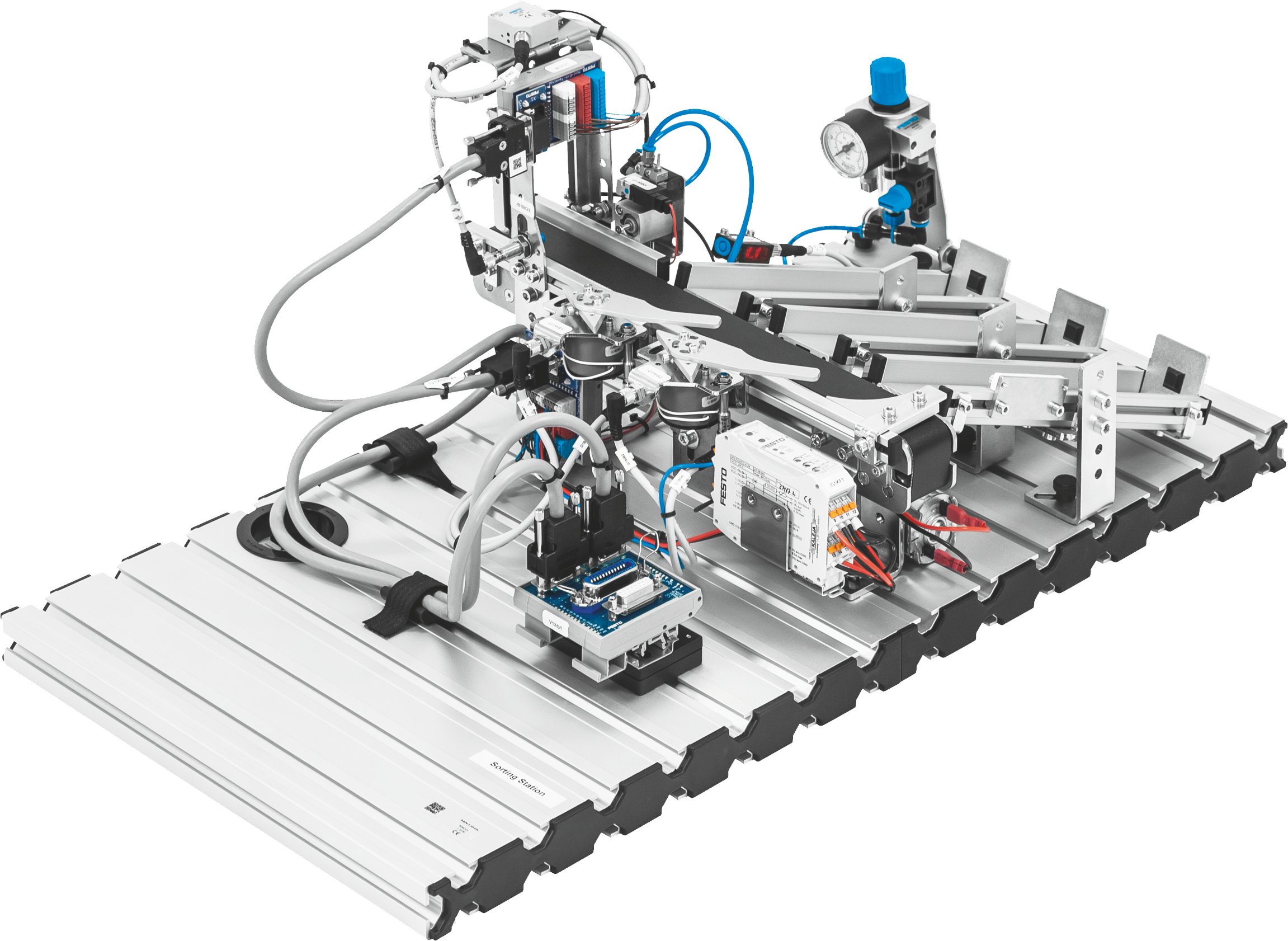

This project centers around the creation of a logic system that digital twins two PLCs (Programmable Logic Controllers) and a robotic arm. These PLCs control two stations, which together illustrate a simplified yet industrially relevant process for basic automation training.

The system demonstrates fundamental automated production functions including separating, feeding, identifying, and sorting. This foundational setup provides a comprehensive training tool, bridging theoretical knowledge with practical application in modern automated production.

Each additional station introduces new learning objectives, enhancing the efficiency of knowledge transfer to real-world automation scenarios. This ensures a robust understanding of automation technology and its practical applications.

For a visual representation of the project and its impact, you can watch the national competition video here: https://www.youtube.com/watch?v=LoUAJeOAlfI

Features:

- Digital Twin: Simulates two PLCs and a robotic arm for automation training.

- Basic Automation Functions: Demonstrates separating, feeding, identifying, and sorting.

- Training Tool: Provides practical experience in automation technology.